Execution: The Power of Doing

Doing is the most underappreciated and unnoticed aspect of success. Doing refers to the act of performing or executing. Doers are extremely valuable in any organization. They are the go-to people (Go-Getters) when trouble arises and magic happens by rolling up the sleeves and doing. There are no right or wrong decisions in doing business – Right decision is the decision that has been successfully executed. (Kulasooriya D M A, 2016).

Doing is the most underappreciated and unnoticed aspect of success. Doing refers to the act of performing or executing. Doers are extremely valuable in any organization. They are the go-to people (Go-Getters) when trouble arises and magic happens by rolling up the sleeves and doing. There are no right or wrong decisions in doing business – Right decision is the decision that has been successfully executed. (Kulasooriya D M A, 2016).

Doing or execution is fundamental to produce results. It is one of the three main pillars of the TDF Model. It is Doers who bring in ideas to real life, which is conventionally termed as innovation in Business Management. The real challenge is to bring in ideas to real life with healthier profits. That’s why many entrepreneurs believe that a lean business process produces right results. A business process is a collection of linked operations, which find their end in the delivery of a valueadded service or a product to a client. New products are results of new processes. Hence, the pertinent question or the challenge that boils in the minds of business leaders is, how to create value with less work. Hence, lean business processes are designed with fewer, simplified and robust operations that are flexible to produce high value-added products & services with the least consumption of resources.

Doing Organizations (DOs)

DOs are made up of a set of lean business processes or lean value chains. DOs are vibrant workplaces (Gemba) where value is created by its employees who willingly and relentlessly engage in producing new ideas and thoughts and bring them in to life with a superior quality.

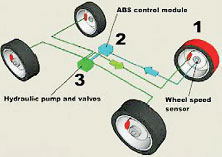

Outputs (Ys) of a lean business process are a function (f) of controllable factors (Xs) and non-controllables (Vs). Ys are called dependent factors (variables) and Xs and Vx are termed as independent variables. Xs are variables that are simply controllable while Vs are variables that are difficult to control. Hence, Vs are called NOISES. For example, In driving, a driver can control the speed (Controllable X) by acting on brakes but reactions being created due to braking such as shocks exerted on passengers, vibration of mounts, slippery of vehicle and wearing of tires cannot be controlled.

All these reactions are called noises, which are uncontrollable without improving the quality of breaking system. If outputs (Y) are safety and speed of driving operation, then you should be able to control both speed and all other noises. Anti-Locked Braking System (ABS) is a good example for safety antiskid braking. However, researches are conducted by leading automobile industries to control other noises also using Taguchi methods (Robust design). Therefore, all DOs should be able to identify all their value chains based on the Doing Algorithm and mange them properly for higher performances. All value chains of DOs to be defined and identified as recipes of the business and that particular recipe is termed as Doing Algorithm (DA).

Doing Algorithm

Y= f (Xs +Vs) Where;

Y = Outputs Xs = Controllable factors

Vs = Noise factors

f = Variation

Quality and the volume of Y depend on the variation (f) of Xs and Vs. Hence, Process Managers, Process Owners and Industrial Engineers should manage the Doing Algorithm for superior performance. Process variations may be due to stability and capability of a given process. For example, think of using eggs in the baking industry. A large egg (standard weight is 60 grams) cracked, yields approximately 3 1/2 tablespoons of liquid.

The yolk will be about 1 1/2 tablespoons and the whites will be about 2 tablespoons. An extra-large egg will have about 4 tablespoons of liquid inside, while a medium egg will have only 3 tablespoons. These differences have no effect whatsoever on omelettes, hardboiled eggs or many other savory dishes, but they can have a big impact on baked products. This changes the ratios given in the recipe and can mean that you’ll end up with a drier or eggier finished product; one not quite as good as would have been achieved with the right sized eggs. In this case, X= number of Eggs being used in recipe while V (Noises) = size of egg, volume of yolk, volume of liquid etc. This shows that controlling Xs are not enough to bring in the ri ght quality but need to control noises as well. The same principle is applied to all industries and their value chains.

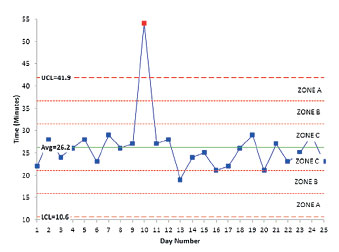

Process Stability

Process stability is the ability of the process to perform in a predictable manner over time. If the process behaves consistently over time, then we say that the process is stable or in control and it is also known as variation reduction. Having identified Xs and Vs is not enough but it is necessary to manage processes to produce consistent results. Process stability is measured in terms of variation and the measure is called standard deviation (sigma) – the perfect partner for process capability. Process stability is measured in terms of variation and the measure is called standard deviation (sigma)- the real measure of quality.  A statistically unstable or out of control process will always produce unpredictable results thus we cannot even determine whether the process can produce quality products. Hence stability of a process comes first before the process capability.

A statistically unstable or out of control process will always produce unpredictable results thus we cannot even determine whether the process can produce quality products. Hence stability of a process comes first before the process capability.

Process Capability (CPk)

Process capability is the measure of ability of the process to meet specifications. It tells us how good the individual output is. All products or services that are out of specifications are called defectives. A defect is anything that does not meet the customer expectations or specifications. Stable and capable lean processes produce quality products and services consistently with the least consumption of resources. Success is in the “DOING”: the second mantra of the TDF model.

Great Qualities of a Certified Doer

Great doers are numbered in any organization. However, human resource specialists have developed some specific training and coaching programs to develop and mould Doers in organizations. Studies show that most of the great doers exhibit the following physiognomies.

- Breakthrough Goal Setter

- Simplifier of theories

- Stalker to grasp next when one fails

- DA (Doing Algorithm) Designer

- The End-In- Minder

- Tech-Savvy

- Do-It –Yourself (DIY) Personality

- Data Lover

- Learner by Doing things

- Disruptive fast mover

It is high time for Business Leaders to headhunt for Great Doers or to develop a pool of Doers within to make sure that their organizations are doing organizations and thriving.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)